Rough Cut Capacity Planning Template

If yous're in the business of planning or forecasting for your organization, then yous've likely heard of Rough Cut Capacity Planning (RCCP).

Do you experience similar you're always backside on your piece of work because you can't seem to get ahead of the demand? Are yous constantly firefighting and putting out one emergency after another?

Rough Cut Chapters Planning is a planning methodology that can help your business overcome these challenges. RCCP uses historical data to predict future need and helps y'all plan for that demand past allocating the necessary resource.

This article will look at RCCP in detail and explain why it's an essential tool for businesses of all sizes. Stay tuned!

Rough cutting capacity planning definition

Rough Cut Capacity Planning is a process that allows you to predict time to come capacity needs and have proactive steps to ensure your organization has the resources it needs to meet those demands. Past anticipating growth and changes in your business, RCCP can assist yous avoid costly oversights and go on your visitor running smoothly.

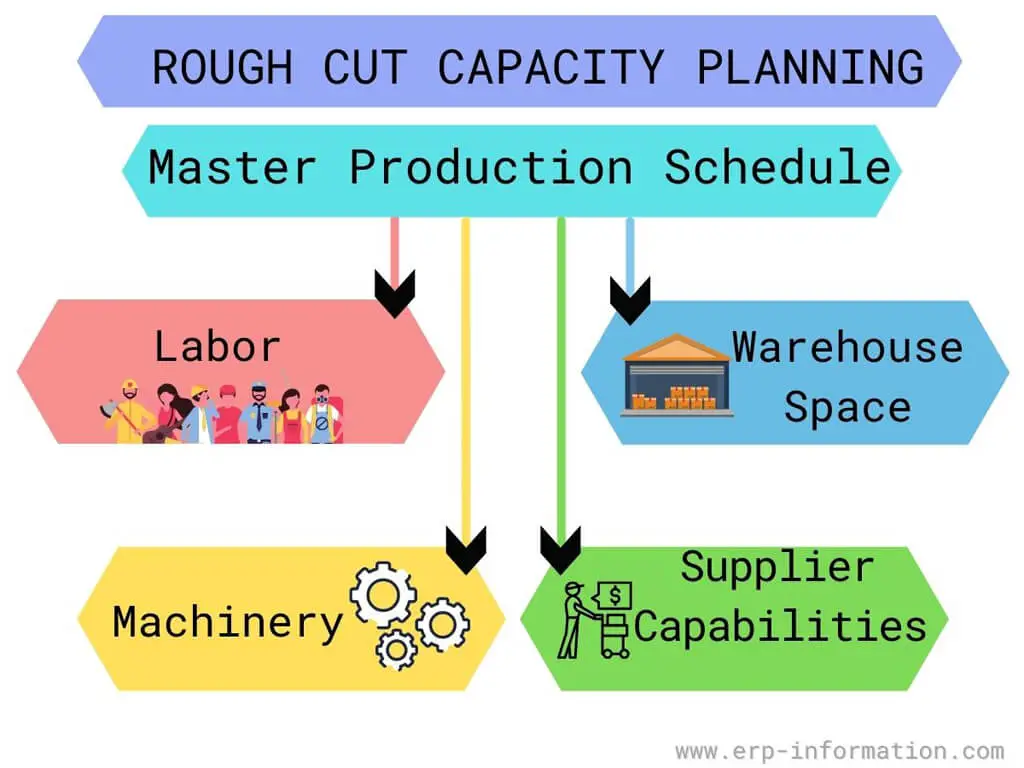

It converts the master production schedule into requirements for critical resources, oft including labor, machinery, warehouse space, and supplier's capabilities.

The concept behind the term Rough cut capacity is that it is the total amount of material required to fulfill the gross requirement of a visitor.

Information technology does not consider scheduled receipts or the on-hand inventory; it calculates the rough cutting amount needed to satisfy the gross requirement.

More on RCCP

Training and planning of the primary schedule planner employ it subsequently, responsible for managing the resources and materials required.

Rough-cutting capacity planning is an piece of cake and simplified technique that does non involve many hidden values or inventories.

Thus, information technology is a streamlined chapters planning, which is more intuitive, organizational, and preliminary.

Rough cutting capacity planning software

The primary functionality ofRCCP software usually comprises matching or balancing the assets available with the demands arising at the moment.

A firm must catechumen its demands into capacity, labor, materials, orders, and finished goods inventory. Therefore, information technology needs to balance its assets and plan accordingly.

Information technology is a model that establishes a computational human relationship betwixt production designs, process sheets, consumption of raw materials, time bachelor, labor availability, etc.

Types of capacity planning

In business organisation management, capacity planning defines how much room companies volition have for additional growth before long without incurring long-term risks or costs. In this sense, it translates into optimizing current assets by judiciously allocating available resources among priorities such every bit development planning, new product introduction, etc., intending to increase overall ROI through efficient resource utilization and strategic resource allotment.

In the case of chapters planning, information technology needs lots of consideration. Hence chapters planning is based on two types,

- Brusque-term capacity planning

- Long-term capacity planning

Curt-term capacity planning

In the instance of the brusque-term programme, the master goal is to increment the production chapters by a few folds and handle the pressure of irregular, unexpected shifts in the face of increased demand.

Managing increased demand needs plenty of changes, but the foremost is to increase production hours, which means overtime for the employees.

Setting up actress facilities and acquiring more materials is also a way to proceed.

Many employees are happy doing overtime, which means extra bonuses and increased wages.

Overtime can go on for a few days or even a few months. Depending on the rush, and also on the other aspects of production.

Long-term capacity planning

Long-term chapters planning is a cumulative effect of numerous short-term outcomes in the case of long-term capacity planning. Increasing shifts temporarily to meet firsthand demands can, in the long run, add to the production chapters if continued.

Opening up a new facility, or increasing hiring and investing in proper preparation, as well increases production capacity in the long run.

Adding capital equipment and modifying the product plan is another opportunity to increase production capacity.

Some manufacturing firms tin can efficiently filibuster demands by backlogging, queuing demands, or managing an anticipatory inventory that takes intendance of sudden rises in society during particular periods.

It allows the business firm to perform at its own stride smoothly.

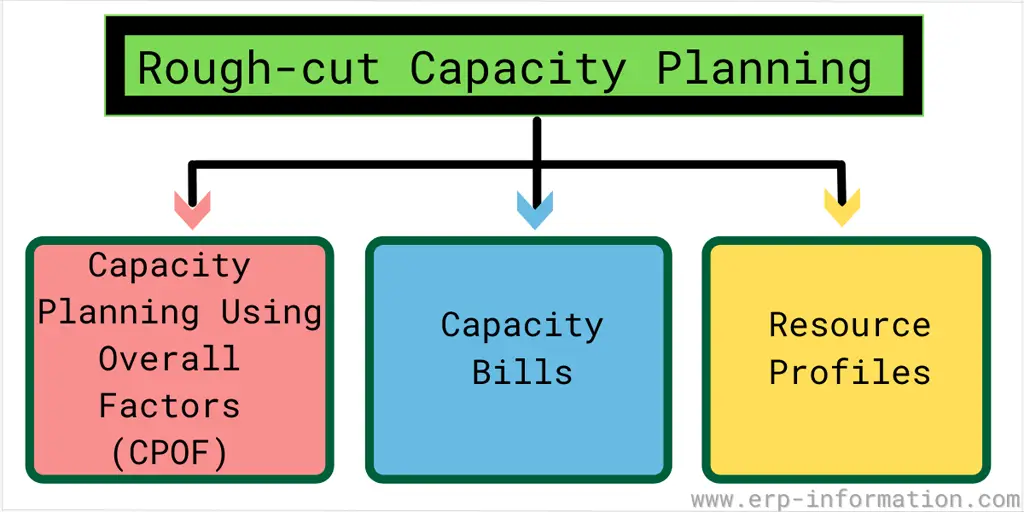

Three methods of Rough cut capacity planning (RCCP)

Capacity Planning Using Overall Factors (CPOF)

Capacity Planning Using Overall Factors (CPOF) is a fast and like shooting fish in a barrel way to judge your chapters needs. This method uses the overall product mix, sales book, and lead fourth dimension to calculate your needed chapters.

Capacity Bills

Chapters Bills is Capacity Planning Using Capacity Factors (CPCF) using Chapters Units, Chapters Expenses, and Chapters Releases. Capacity Bills give more detailed figures than CPOF. However, the results are highly accurate.

Resource Profiles

Resource Profiles look at your resource by product/catamenia (e.yard., monthly). Resources profiles testify you how many resources you will need and when. Resource profiles provide more accurate estimates than Capacity Bills but take more fourth dimension and endeavor.

Rough cutting capacity planning examples

Allow us take the instance of a factory that produces two items, boots, and sandals. An MPS adding takes place before the product of the pieces begins.

The amount of textile required and the necessary working hours are calculated.

A crude-cut capacity planning includes charting out the,

- staff hours necessary to fulfill the job

- the units required

- several days that will exist needed to complete the task eventually

- the amount of material that needs to be purchased.

This chart would not consider inventory management details or scheduled late inflow receipts. Hence a crude cut capacity planning schedule is simple, intuitive, and similar to organizational planning to chart out the requirements in a rough estimation.

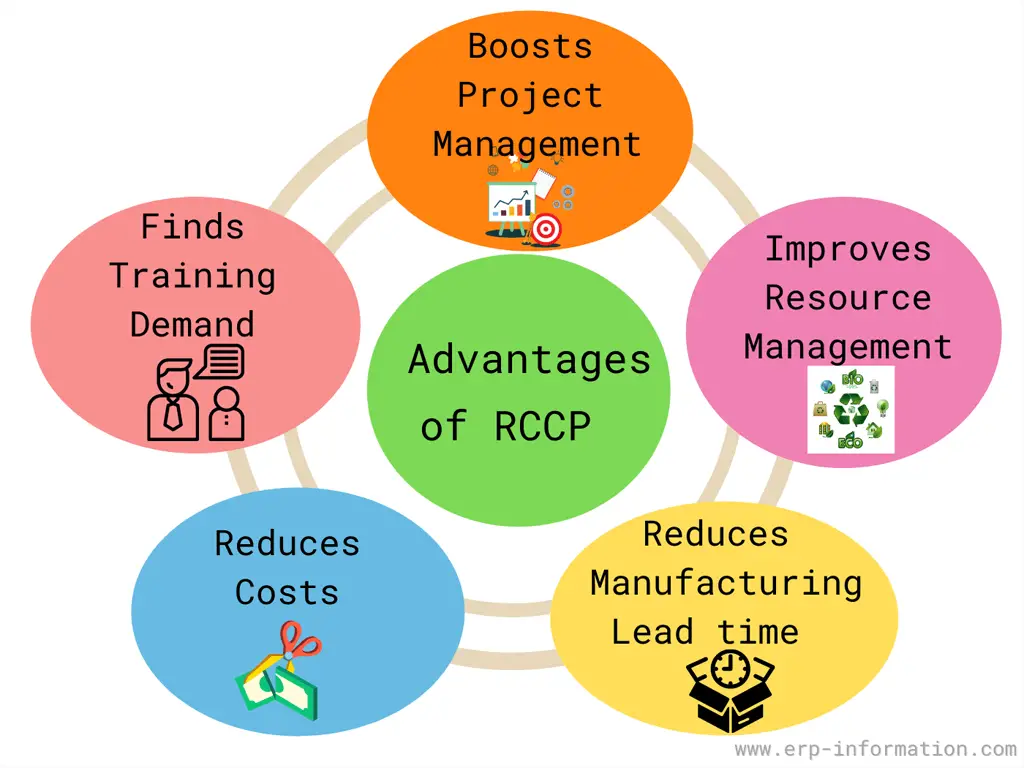

Some advantages and disadvantages of rough-cutting capacity planning are mentioned here.

Advantages and Disadvantages

Advantages

Boosts project direction

You tin can quickly identify which work should start outset and which job you can start afterwards because of crude cut capacity planning.

Hence y'all and your squad make sure well-nigh your work priority. In this style, it improves your project direction.

Improves resources management

You can get a clear thought of the resources available and the working hours required for each procedure in each workstation.

Hence yous can apace identify the more or less workload and adjust the capacity by increasing or decreasing the shifts and increasing the number of workstations.

Decreases manufacturing lead fourth dimension

Rough cut capacity planning helps the manufacturer find out the problems in the manufacturing procedure and allows him to address the trouble immediately. Hence it reduces the manufacturing pb fourth dimension.

Reduces costs

Knowing your team'south chapters can forecast how you can take on many training projects in a given period. That helps to bring downward costs by reducing the waste product on the training team.

Helps to detect training demands

It allows you to bank check out the training need depending on the available resources like working hours, budget, and skills.

What is the drawback of rough cutting chapters planning?

- It can consume time if your organization is large.

- It needs more discipline. You should update the schedule consistently. Otherwise, there will be a lack of discipline.

Difference betwixt RCCP and CRP

| RCCP | Capacity Requirement Planning (CRP) |

| It is used in the starting time planning stage for the principal product schedule. | It is usable for the concluding capacity check for the primary production schedule. |

| It gives rapid feedback. | It gives feedback slowly. |

| It is less precise comparatively. | Information technology is more precise. |

What is rough cut capacity planning in SAP?

Rough cut capacity in SAP is a collection of outlooks on the organization'southward resources. That means the system considers one whole working twenty-four hours instead of hours and minutes and considers work heart groups instead of a single work heart.

SAP capacity planning predicts hereafter needs based on available resources and predictable demands. This type of planning is a wide-ranging activity that involves decisions related to people, processes, products, equipment, and finances.

Conclusion

RCCP stands for crude-cut capacity planning. RCCP is a process that helps manufacturers guess the number of units they tin can produce in a given menses, and information technology'due south an integral role of manufacturing.

With the proliferation of data and information, it has become increasingly difficult for organizations to conceptualize demand. As a result, many businesses take turned to rough-cut capacity planning as an effective way to ensure they can fulfill client orders on time without sacrificing quality or exceeding their budget.

The goal is not just well-nigh meeting firsthand needs but also existence proactive with hereafter growth by ensuring that in that location are no bottlenecks in production before they occur.

RCCP in manufacturing provides a methodology that combines these ii aspects with cost-effective tools for optimizing productivity levels beyond your organization's operations.

The rough-cut capacity planning technique has various advantages and disadvantages, only information technology is considered a safe starting point.

Rough Cut Capacity Planning Template,

Source: https://www.erp-information.com/rough-cut-capacity-planning-details

Posted by: laportepuldivis.blogspot.com

0 Response to "Rough Cut Capacity Planning Template"

Post a Comment